Projects

Engserj is ready to work on projects in different sectors.

Thanks to the experience acquired in almost 40 years of operation, the company achieved great feats in engineering and became a reference in its field. Currently, Engserj collects successful projects, developed for small, medium and large companies.

Industrial

Automotive

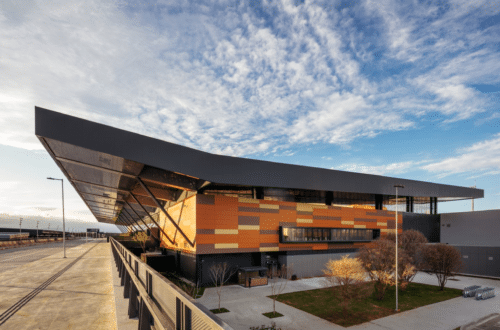

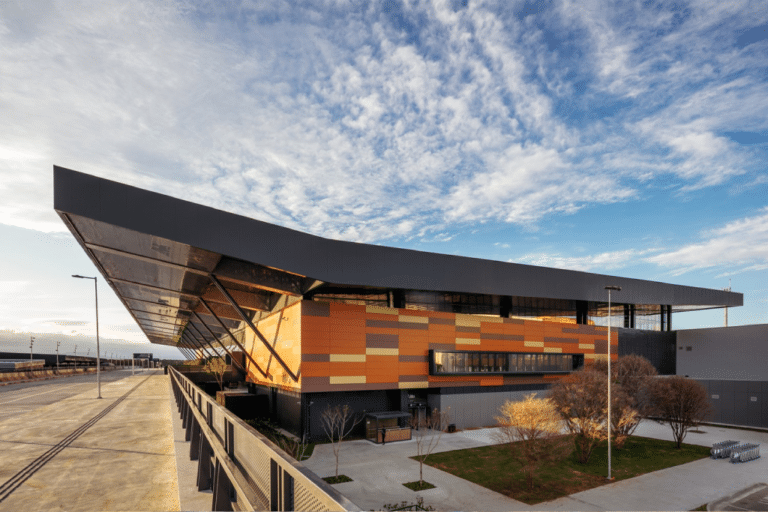

USIMINAS – STAMPING WAREHOUSE

USIMINAS – STAMPING WAREHOUSE

Customer

Place

Descriptive

Architectural design, foundations and structures, comprising the foundations of the stamping shed II, with foundations for equipment, expansion of the changing room / toilet, the new electrical room, the new cooling tower and foundations of the scrap conveyor.

Beverage and Food

AMBEV – JACAREÍ DUPLICATION

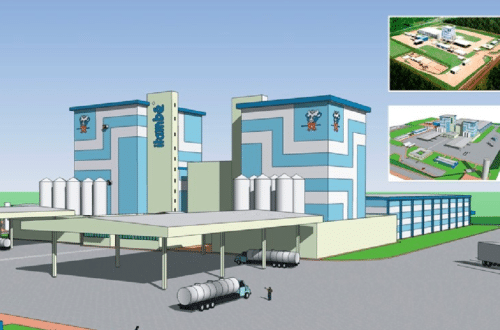

ITAMBÉ – UBERLÂNDIA FACTORY

ITAMBÉ FACTORY EXPANSION

AMBEV – JACAREÍ DUPLICATION

Customer

Place

Descriptive

Design of foundations and structures related to the duplication of the Ambev factory, covering all units of the plant: equipment, buildings and infrastructure.

ITAMBÉ – UBERLÂNDIA FACTORY

Customer

Place

Descriptive

Multidisciplinary project for the powdered milk factory with a production capacity of 1 million liters of milk/day and a project to duplicate it for 2 million liters of milk/day.

ITAMBÉ FACTORY EXPANSION

Customer

Place

Descriptive

Architecture, earthworks, paving, foundations, concrete structures, metallic structures, electrical, hydraulic, CCTV, SPDA, air conditioning, exhaust and utilities projects. Expansion of the milk cream and condensed milk line to 600,000 liters of milk/day.

Cement

CIMENTO NACIONAL – SETE LAGOAS EXPANSION

PETROCAL FERTILIZERS FACTORY

CIMENTO NACIONAL – SETE LAGOAS EXPANSION

Customer

Place

Descriptive

Executive design of foundations/bases and concrete structures for equipment and buildings and various metallic structure projects.

PETROCAL FERTILIZERS FACTORY

Customer

Place

Descriptive

Preparation of a multidisciplinary project including:

-

Architectural Preliminary Design;

-

Executive Design of architecture, foundation, concrete structures, plumbing and sanitary systems, fire protection, and infrastructure for auxiliary buildings;

-

Executive Design of foundations and concrete structures for the units in the industrial area.

Mining

MARCARENHAS BARBOSA ROSCOE

THYSSENKRUPP

GERDAU – P1, P3, and Blending Yard

CSN – RAILWAY ROUNDHOUSE

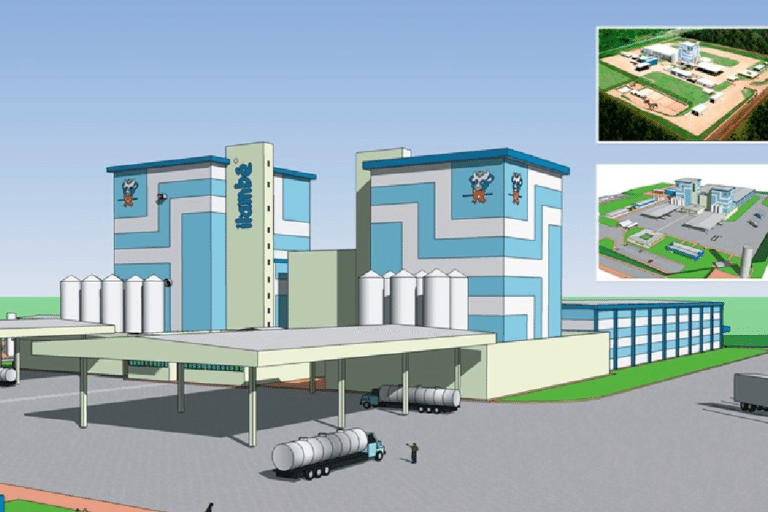

ANGLO AMERICAN

VALE

MARCARENHAS BARBOSA ROSCOE

Customer

Place

Descriptive

Development of foundation designs for the thickeners at the Conceição, Cauê, and Brucutu mines.

Preparation of detailed engineering designs for the Tailings Filtration Project – PDR Cava – Brucutu, São Gonçalo do Rio Abaixo/MG.

Provision of design compliance assessment services for precast structures of the Primary and Secondary Crushing Buildings for VALE – Itabira.

THYSSENKRUPP

Customer

Place

Descriptive

Design of Wagon Tipplers VV 01, 02, and 03 for VALE in São Luís, Maranhão;

Structural verification of the travel path for the replacement of the Stacker/Reclaimer E/R-1 at the CSN yard in the Sepetiba Port – TECAR, in Itaguaí, Rio de Janeiro

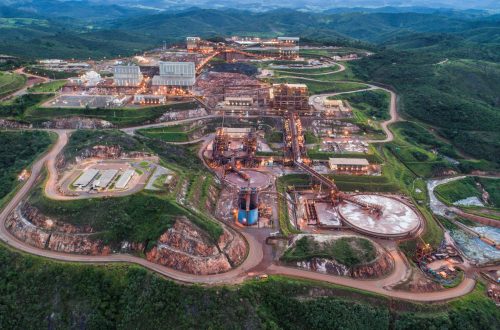

GERDAU – P1, P3, and Blending Yard

Customer

Place

Descriptive

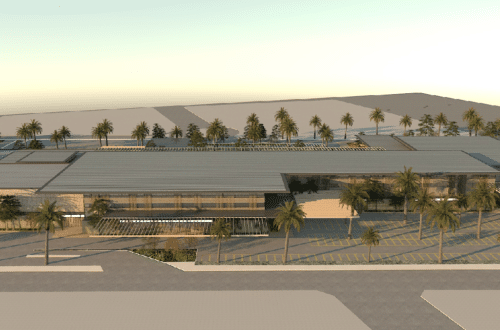

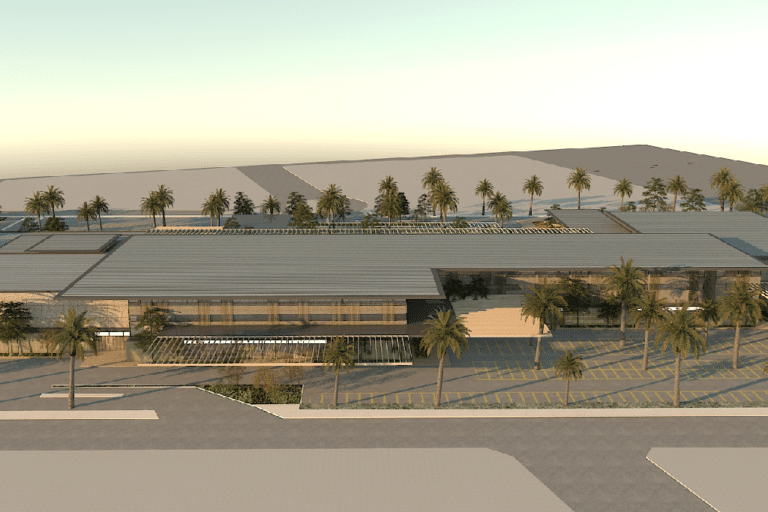

Validation of the Basic Design and development of the Multidisciplinary Detailed Design, including BIM coordination, for the capacity expansion of Yards P1, P3, and Blending Yard:

Architecture, Earthworks, Drainage, Paving, Foundations, Reinforced Concrete Structures, Steel Structures, Electrical Systems, Communication Networks, Lightning Protection System (LPS), Automation, Mechanical Systems, Piping, Plumbing Installations, Air Conditioning, and Exhaust Systems.

CSN – RAILWAY ROUNDHOUSE

Customer

Place

Descriptive

Design of foundations, concrete structures and inserts of a single and a double railway roundhouse for CSN in the Port of Itaguaí and for the following units: control rooms, electrical panels, hydraulics and cable basement; access tunnels; railway carriage positioner; sieving building; hoope cap. 30 tons; substations; belt conveyors and transfer towers; sampling tower; provisional unloading station for railway carriages and others.

ANGLO AMERICAN

Customer

Place

Descriptive

Soil Consulting, Planning and Multidisciplinary Executive Projects for the administrative and support buildings of the iron ore processing plant, located in the municipalities of Conceição de Mato Dentro and Alvorada de Minas – MG.

VALE

Customer

Place

Descriptive

Various engineering designs under the Umbrella Contract in Carajás and the Southeast region.

Foundation design for the Reclaimer/Stacker of the Pellet Stockyard, Yard 8, for Vale in Vitória – ES.

Project L3334 – TIPLAM Expansion: Preparation of the ACP – verification of the steel and concrete structure designs for the Grain, Soybean Meal, and Sugar Storage Building

Oil and Gas

TRANSPETRO

PETROBRÁS – SUBSTATIONS

TRANSPETRO

Customer

Place

Descriptive

Preparation of executive projects divided into six deployment sites for Transpetro:

-

1 EMED and 1 Prover for the São Sebastião Terminal;

-

4 EMEDs, 3 Electrical Centers, and 4 Provers for the Paulínia Refinery;

-

4 EMEDs, 1 Electrical Center, and 4 Provers for the São José dos Campos Refinery;

-

1 EMED, 1 Electrical Center, and 1 Prover for the Duque de Caxias Refinery;

-

1 EMED, 1 Electrical Center, and 1 Prover for the Cabiúnas Terminal;

-

1 EMED and 1 Prover for the Campos Elísios Terminal.

Scope included:

-

Design of foundations and containment basins;

-

Earthworks design defining cut and fill volumes and excavation material quantities;

-

Pavement and roadway design for the creation of access flooring to the mobile prover basin;

-

Road signage project;

-

Stormwater drainage design including runoff and capture from the EMEDs, Electrical Centers, and Mobile Provers’ roofs;

-

Oily water drainage system design, capturing residues from inside the EMED and Mobile Prover basin areas;

-

Determination of the anchoring embedment length for equipment, pipe supports, and steel structures on concrete bases;

-

As-built drawings of the projects developed based on field surveys marked on printed copies of the design.

PETROBRÁS – SUBSTATIONS

Customer

Place

Descriptive

Executive projects of architecture, foundation, superstructure, metallic structure and hydro-sanitary for nine substations. Structural project of envelopes and junction/passage boxes for substation interconnection.

Steel Industry

GERDAU – FINISHING MILL

GERDAU – PLATE MILL ROLLING MILL

V&M – RK STRIP ROLLING MILL

USIMINAS – COSIPA HOT STRIP ROLLING MILL

GERDAU – PROFILE STRIP ROLLING MILL

AVB – STEEL WORK AND ROLLING MILL

GERDAU – STECKEL STRIP ROLLING MILL

GERDAU – FINISHING MILL

Customer

Place

Descriptive

Finishing Mill project, with approximately 12,000 m³ of concrete, comprising:

-

Executive design of foundation piling (for Equipment and Hydraulic Rooms), with specialized geotechnical consulting (definition of foundation types, load-bearing capacity, pile lengths, etc.);

-

Executive design of excavations and backfills below the completed grading levels;

-

Executive designs for the foundations of equipment, hydraulic rooms, piping and electrical galleries, electrical rooms, control rooms, and coil storage yards;

-

Architectural and structural designs for the electrical rooms, pulpit, and control room;

-

Structural design of drainage boxes and channels, including trench drains at the building entrances;

-

Grounding grid design and interconnection with the main grounding network to meet equipment requirements;

-

Design of guardrails/handrails for stairs and openings, as well as covers for openings;

-

Preparation of As-Built drawings based on field surveys marked on project copies provided by PARANASA;

-

Preparation of 3D AutoCAD drawings with a high level of detail, based on 2D drawings, for the foundations of all equipment and structures;

-

Foundation design for the main building;

-

Verification of the foundations in the existing design of the Secondary Cutting Building.

GERDAU – PLATE MILL ROLLING MILL

Customer

Place

Descriptive

Plate Mill project, with approximately 90,000 m³ of concrete, comprising:

-

Quality Control Plan (QCP) for the load map of the rolling mill building, including high-capacity overhead cranes and a ceiling height of approximately 20.0 m;

-

Structural steel design for the support structure of the Mulpic Tank, with an area of 12.0 m x 24.0 m and a height of 26.0 m;

-

Design of electrical rooms with reinforced concrete basement and steel structure for the superstructure/roof;

-

Structural steel design for the control pulpits of the Finishing Mill, Hot Leveler, Cooling Bed, Dividing Shear, Plate Inspection, Plate Storage, Cold Leveler, and Ultrasonic Testing Station;

-

Structural steel design of the Pipe-Rack for the Mulpic Water Treatment system;

-

Executive design of foundation piling (for Equipment, Electrical and Hydraulic Rooms);

-

Executive design of excavations and backfills below the grading level;

-

Executive designs for the foundations/bases of equipment, hydraulic rooms, piping and electrical galleries, electrical rooms, locker room, control rooms, slab and scrap storage yards, and the slow cooling/gas cutting yard for slabs;

-

Architectural, site development, and structural designs for the electrical rooms, pulpits, control room, locker room, and temporary bridge;

-

Geometric and pavement design for access roads to the main building;

-

Structural design of drainage boxes and channels, including trench drains at the building entrances;

-

Grounding grid design;

-

Foundation design for the main building and concrete structures of the Mulpic Water Treatment system;

-

Preparation of 3D AutoCAD drawings with a high level of detail for the foundations of all equipment and structures.

V&M – RK STRIP ROLLING MILL

Customer

Place

Descriptive

- Design of the new RK Continuous Rolling Mill, including the design of foundations, shoring, concrete structures (bases), reinforcement of existing structures, covering the following equipment/units:

- Mandrel Adjustment

- Oven input table

- Rotary Kiln Outlet Conveyor System

- Block Reducing Strip Rolling Mill / Magnifying Glasses

- Oblique Strip Rolling Mill (SWW)

- Continuous Strip Rolling Mill KWW

- Output of the Continuous Strip Rolling Mill (KWW)

- Reeler Strip Rolling Mill

- Cooling Bed I

- Reheat Furnace

- Hydraulic Stripper

- Stretcher Reducer Laminator

- Cooling Bed II

- Hydraulic Holds I, II and III

- Electric Basements I, II and III

USIMINAS – COSIPA HOT STRIP ROLLING MILL

Customer

Place

Descriptive

Tropicalization of Projects and Preparation of frame designs for foundations and equipment bases for Hot Strip Rolling Mill Project No.2.

GERDAU – PROFILE STRIP ROLLING MILL

Customer

Place

Descriptive

Structural profile rolling mill project, including chair repositioning project, including transfer table foundation demolition project, foundation slab reinforcement project and chair bases, and foundation project for new area/handling equipment and design of industrial floors.

AVB – STEEL WORK AND ROLLING MILL

Customer

Place

Descriptive

Multidisciplinary executive design of the entire Steelmaking and Rolling Mill plant, comprising:

-

Executive design of foundations and concrete structures for equipment and external units (dedusting systems, water and wastewater treatment, water intake, oxygen plant, main substation, etc.);

-

Multidisciplinary executive designs for support buildings.

GERDAU – STECKEL STRIP ROLLING MILL

Customer

Place

Descriptive

Steckel Mill project with approximately 70,000 m³ of concrete, comprising:

-

Executive design of the foundation piling;

-

Executive design of diaphragm wall retaining structures;

-

Design of excavations and backfills below the grading level;

-

Executive designs for the foundations of equipment, hydraulic rooms, piping and electrical galleries, electrical rooms, locker room, two control rooms, coil and slab storage yards, and the Steckel WTP (Water Treatment Plant);

-

Executive designs of the reinforced concrete structures of the Steckel WTP;

-

Detailing design of the connections between the steel structure and the steel-deck slabs;

-

Architectural, plumbing and sanitary, electrical (lighting and outlets), telephone, and fire protection designs for the electrical rooms ER2 and ER3, pulpits, locker room, and two control rooms;

-

Geometric and pavement design;

-

Grounding grid design;

-

Preparation of 3D AutoCAD drawings with a high level of detail for the foundations of all equipment and structures.

Paper and Celulose

DURATEX – EXPANSION

DURATEX (SATIPEL) – FACTORY EXPANSION RS

DURATEX – EXPANSION

Customer

Place

Descriptive

Multidisciplinary executive projects for the plant’s equipment and buildings, such as: production shed, MDF production line and finishing line, power plant, refiner and refining tower, chip silo, dried biomass silo, cyclone, filters, gas scrubber, hydraulic room and chimney, water reservoir and pump room, substations, waste center, drivers rest room and concierge.

Expansion of the factory in Taquari – RS

DURATEX (SATIPEL) – FACTORY EXPANSION RS

Customer

Place

Descriptive

-Executive projects for geometric earthworks/street paving and surface protection (vegetation) of the expansion area (including new access);

– Rainwater drainage project for the expansion area, including calculation of existing rainwater contributions for its interconnection in the new networks;

-Architecture, foundation, structure and floor design in reinforced concrete for the Building for the MDP Panel Production and Storage Line and also for the New Warehouse. Including supports for utility pipes;

-Project of foundations for the MDP Panel Production and Storage Line equipment;

-Executive project of architecture, foundation, structure and floor in reinforced concrete of the support buildings, internal and external to the Production Building;

-Preparation of advanced Quantities Spreadsheet for civil works bidding.

Infrastructure

Airport

CONFINS INTERNATIONAL AIRPORT

FLORIANÓPOLIS AIRPORT

MACAÉ AIRPORT

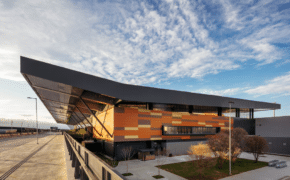

CONFINS INTERNATIONAL AIRPORT

Customer

Place

Descriptive

Development of multidisciplinary designs for the following units:

-

Passenger Terminal – TPS 1 (Renovations/Structural Reinforcements)

-

Passenger Terminal – TPS 2 (Concrete Structures)

-

Passenger Terminal – TPS 3 (Renovations /Structural Reinforcements)

-

Boarding Bridges – (Multidisciplinary Designs)

-

Utilities Center – CUT 2 (Multidisciplinary Designs)

FLORIANÓPOLIS AIRPORT

Customer

Place

Descriptive

Development on the BIM platform of the basic and executive project of foundations and structure in reinforced concrete cast in loco and precast (blocks, beams, slabs and pillars) and basic and executive project of metallic structure (calculation and project drawings with details of the connections main), of the following airport units: Terminal, including boarding bridges; CUT; Fire Department; clinic; access viaduct to the boarding area in a mixed structure, including: terminal floor, CUT, fire department and charlie access.

MACAÉ AIRPORT

Customer

Place

Descriptive

Development on the BIM metodology of the conceptual, basic and executive projects of the foundation and structures in concrete and steel of the following airport units:

- New passenger terminal;

- Utility center;

- Hangar Type 1;

- hangar type 2;

- Guardhouse – gate C;

- Lighting towers – foundations only;

- Jet Blast barrier – foundations only.

Artworks

SPECIAL ENGINEERING STRUCTURES – LINHA VERDE

EQUATORIAL GUINEA

PRAINHA VIADUCT

ANTÔNIO CARLOS AVENUE DUPLICATION

RECIFE METROPOLITAN TRAIN

LAGOINHA HYPERCENTRO VIADUCT

SPECIAL ENGINEERING STRUCTURES (SES) – PARAUAPEBAS–CANAÃ DOS CARAJÁS

SPECIAL ENGINEERING STRUCTURES – LINHA VERDE

Customer

Place

Descriptive

Preparation of the executive design for foundations and structures of the following engineering structures (OAEs) on Cristiano Machado Avenue, in Belo Horizonte:

-

2 viaducts and an underpass at the intersection with José Cândido da Silveira Avenue;

-

2 viaducts at the intersection with Bernardo Vasconcelos Avenue;

-

Box culvert for the Cachoeirinha Stream;

-

Covers for the Pampulha Canal.

EQUATORIAL GUINEA

Customer

Place

Descriptive

Development of studies and executive project for the construction of bridges and viaducts in the Equatorial Guinea, Africa.

Development of basic project for the bridge decks including study of alternatives of prestressed and reiforced concrete framework and metal section including the concrete slab (composite structure).

Development of executive projects of foundations, mesostructure, and superstructure for the following artworks: Bridge over the Chiguô River, doube bridge measuring 60 meters length and 11.3 meters wide each, bridge over the Abiá River, double bridge measuring 84 meters in length and 11.3 meters wide each, double viaduct at intersection 3 measuring 64 meters in length and 115 meters wide each, single viaduct at intersection 4 measuring 64 meters in length and 12.8 meters wide, and double viaduct at intersection 5 measuring 80 meters in length and 22.5 meters wide each.

PRAINHA VIADUCT

Customer

Place

Descriptive

Project of foundations and structures for the Prainha Viaduct, with 6,681 m², a length of 510 meters, spans of 40 to 43 meters, in successive cantilevers in prestressed concrete with precast voussoirs and pillars in sliding form. Pillars up to 95 meters high.

ANTÔNIO CARLOS AVENUE DUPLICATION

Customer

Place

Descriptive

Elaboration of the preliminary design and executive project for the following Special Engineering Structures:

-

3 viaducts at the intersection with Antônio Abrahão Caram Avenue;

-

2 viaducts at the intersection with Marechal Espiridião Rosas Avenue;

-

2 viaducts at the intersection with Operários Street;

-

2 viaducts at the intersection with Araribá Street;

-

2 viaducts at the intersection with Formiga Street;

-

2 viaducts at the intersection with Rio Novo Street;

-

Lateral retaining structures at the viaduct abutments.

RECIFE METROPOLITAN TRAIN

Customer

Place

Descriptive

Development of detailed foundation and structural designs for:

-

Double-track railway viaduct, 657.80 meters in length, with spans using prestressed precast beams and one span with inverted beams;

-

Railway viaduct over Travessa do Raposo;

-

Bridge (Freight Line) over the Dead Arm of the Capibaribe River;

-

Railway bridge and pedestrian overpass over the Tejipió River.

LAGOINHA HYPERCENTRO VIADUCT

Customer

Place

Descriptive

Development of the foundation design, mixed concrete and steel box structure with reinforced concrete slab.

Viaduct with a length of 318 meters, featuring both horizontal and vertical curves, and spans ranging from 22 to 42 meters.

SPECIAL ENGINEERING STRUCTURES (SES) – PARAUAPEBAS–CANAÃ DOS CARAJÁS

Customer

Place

Descriptive

Design of Bridges and Overpass on the Parauapebas–Canaã dos Carajás Highway

Included the design of six bridges and one overpass with a composite deck structure (steel girders and reinforced concrete slab) for rural access roads, as part of VALE’s Sossego Project.

Sanitation

SEWAGE TREATMENT STATION – ONÇA

SEWAGE TREATMENT STATION – ARRUDAS

WATER TREATMENT STATION – RIO DAS VELHAS

SEWAGE TREATMENT STATION – ONÇA

Customer

Place

Descriptive

Development of detailed designs for the following units:

-

Primary and Secondary Digesters

-

Post-tensioned Concrete Thickeners

-

Grit Chambers

-

Channeling of the Rodrigues da Cunha I Stream

-

Access Bridges

-

Suspended Channels

-

Pumping Stations

-

Centrifuge Building

-

Metering Cabinet

-

Control Room for Pumping Stations

-

Equipment Foundations

SEWAGE TREATMENT STATION – ARRUDAS

Customer

Place

Descriptive

Development of foundation and structural designs for the first and second implementation phases of the Vale do Ribeirão Arrudas Sewage Treatment Plant:

-

Foundation and structural designs for the Pumping Station, Primary Clarifiers, Primary Digesters, Anaerobic Digesters, Effluent Galleries, Grit Chambers, and Administrative Buildings;

-

Surface Drainage Design for the Clarifier and Primary Digester Plateaus;

-

Drainage Design for the Access Road to the Substation.

WATER TREATMENT STATION – RIO DAS VELHAS

Customer

Place

Descriptive

Foundation and structural design for the Rio das Velhas water production system, covering the following units:

-

High-Pressure Pumping Station;

-

3rd Line Water Main;

-

Storage and Compensation Reservoirs.

Other notable projects

RIO 2016 OLYMPIC PARK

PITUAÇU PASSENGER TERMINAL

TOLL PLACES VIA 040

RIO 2016 OLYMPIC PARK

Customer

Place

Descriptive

Development of infrastructure designs for the Olympic Park of the RIO 2016 Olympic Games, covering an area of approximately 120 hectares, including:

-

Analysis and validation of the conceptual design;

-

Basic and detailed designs for road and platform geometry and earthworks, paving, foundations, geotechnics, and reinforced concrete structures;

-

Basic and detailed designs for surface and deep drainage systems, including the networks for collection and conveyance of stormwater from roadways, plazas, and parking areas to the boundary of the complex, with detailed drainage components.

PITUAÇU PASSENGER TERMINAL

Customer

Place

Descriptive

- Project Compliance Assessment for the Steel Structures of the Pituaçu Passenger Terminal;

- Preparation of the Terminal Foundation Designs;

- Development of the Inspection and Maintenance Manual for the Terminal Structures, with a special focus on the steel structure.

TOLL PLACES VIA 040

Customer

Place

Descriptive

Development of multidisciplinary projects for the following units in the stretch from Brasília/DF to Juiz de Fora/MG, with an extension of 936.8 km:

project of operational bases and user service system (sau); design of toll plazas and weighing stations.

Buildings

Large-sized

2014 WORLD CUP – MINEIRÃO

MUSICARIUM BRAZILIAN PHILHARMONIC ACADEMY

DOM CABRAL FOUNDATION

2014 WORLD CUP – MINEIRÃO

Customer

Place

Descriptive

Complete basic and executive project of foundations, containments, structures in reinforced/prestressed concrete and metallic structures suitable for FIFA prerequisites, sustainability (for LEED accreditation) and other relevant standards and legislation (fire prevention and fighting, accessibility, etc.), for the internal and external areas of the stadium.

Land of 233,159.97 m², with a total constructed area of 317,575.00 m².

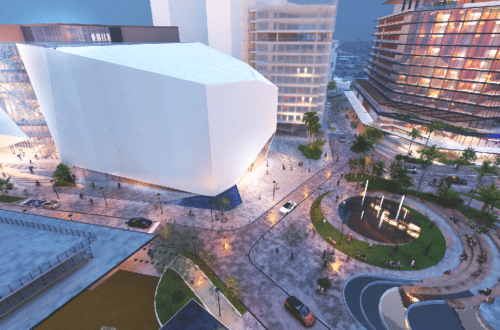

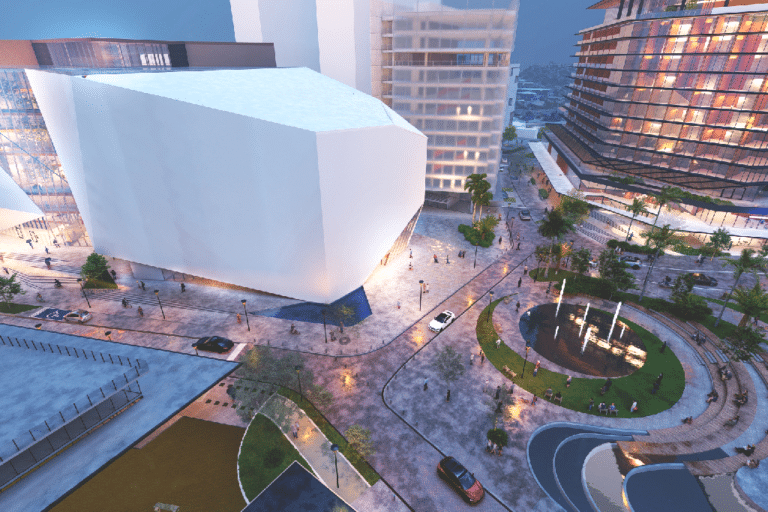

MUSICARIUM BRAZILIAN PHILHARMONIC ACADEMY

Customer

Place

Descriptive

Musicarium Academia Filarmônica Brasileira Development on the BIM platform of the conceptual and basic project of foundation, containment, concrete structures and steel structures for a building with an area of approximately 22,000 m².

DOM CABRAL FOUNDATION

Customer

Place

Descriptive

Project of foundations, containments, locking structures, slabs, raised and buried reservoirs of the training center, at Alphaville Lagoa dos Ingleses – in Nova Lima/MG; Execution of structural and foundation projects for the Management Knowledge Development Center at Alphaville Lagoa dos Ingleses, in Nova Lima/MG.

Shopping mall

LUIZ EDUARDO MAGALHÃES

VALE DO AÇO SHOPPING MALL

DIAMOND MALL

TAGUATINGA SHOPPING MALL

LUIZ EDUARDO MAGALHÃES

Customer

Place

Descriptive

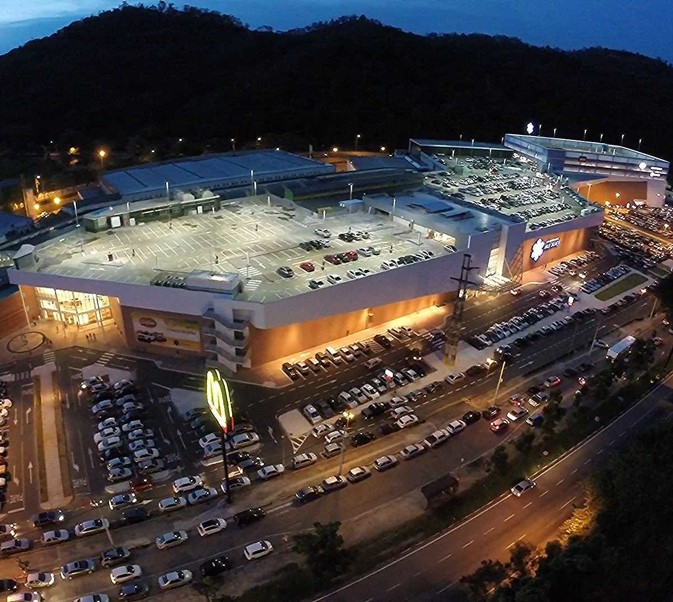

Development of the basic and executive design of the foundation and structures in concrete and steel structures for a building with an area of approximately 40,000 m².

VALE DO AÇO SHOPPING MALL

Customer

Place

Descriptive

Development of foundation projects and structures in concrete and steel for the extensions of Vale Shopping Mall.

DIAMOND MALL

Customer

Place

Descriptive

Project of foundations, containments, reservoirs and concrete structures with 75,000 m² of built area, on seven levels.

TAGUATINGA SHOPPING MALL

Customer

Place

Descriptive

Development of the executive project of two cores in reinforced concrete with an area of 6,340 m² and a height of 79.5 m that are part of the horizontal bracing of the building for the expansion of Shopping Taguatinga, having Atrium Empreendimentos Imobiliários S.A. , located at Rua 210 QS 01 Lot 40 Águas Claras, Taguatinga–DF.

Hospital

UNIMED BETIM

TERESINA EMERGENCY ROOM

UNIMED BETIM

Customer

Place

Descriptive

Development of foundation projects, concrete structures and metallic structure for the new Unimed hospital in Betim, MG.

TERESINA EMERGENCY ROOM

Customer

Place

Descriptive

Development of multidisciplinary projects, related to the municipal emergency hospital of Teresina – PI, with 12,500 m² of built area and capacity for 167 beds.